Marine Propulsion Systems | Definition, Types and Uses Explained

Introduction

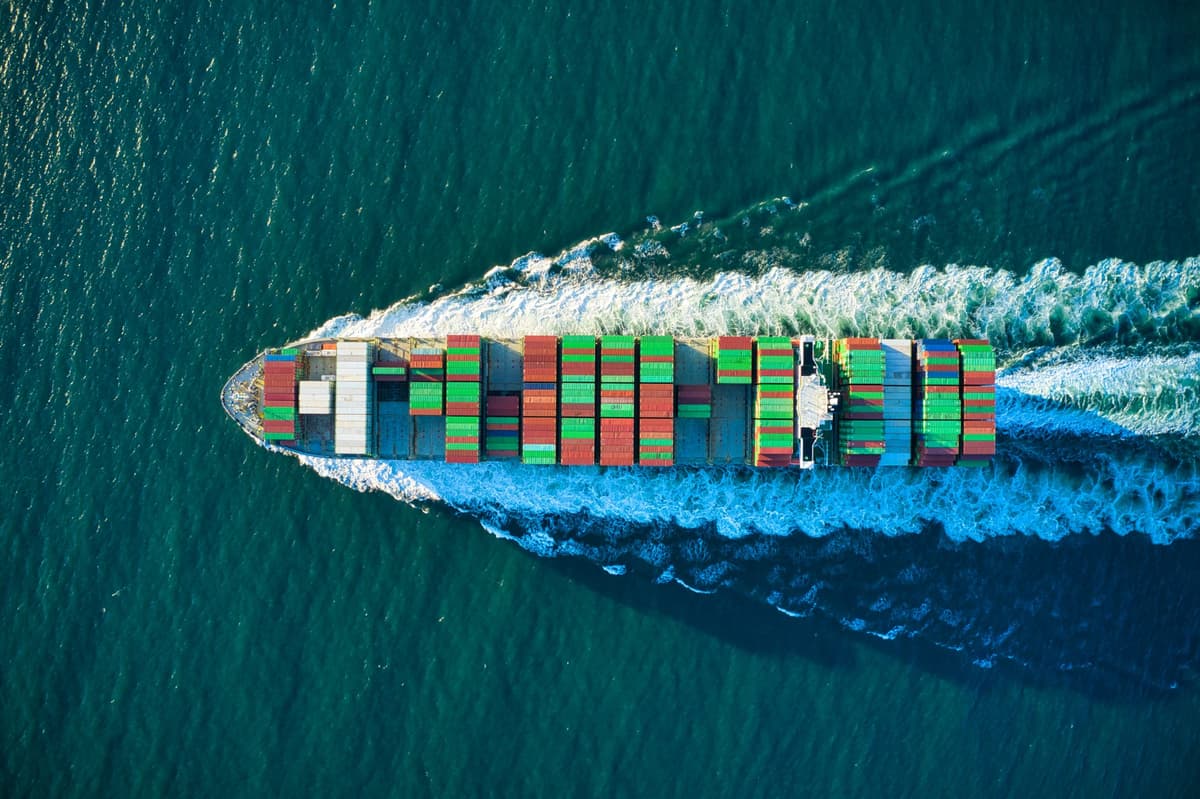

Marine propulsion refers to the methods of propelling ships through the water. We have come a long way since we first started exploring the seas through paddles and oars. Today, we have many different types of propulsion systems.

In this article, we will give a brief overview of the different types of marine propulsion methods available and how they work. Let’s start by defining marine propulsion.

What is a marine propulsion system?

A marine propulsion system refers to the technology that propels any water-borne craft on the water. All marine propulsion systems work on Newton’s third law of motion whereby any force applied by one object to a second object results in an equal reaction force being applied on the first object.

In the case of marine propulsion, the propulsion device applies a force on either the surrounding water or air to create a reaction force on the craft and push it in the required direction.

This can be seen in the case of propellers that push the water aft (or forward), and are subjected to an equal force in the forward (or aft) direction. If this force is large enough, it moves the craft on the water. The same is true for hovercraft fans or wind sails where the forces are applied to the surrounding air.

Different types of marine propulsion systems

We shall be covering the following types of marine propulsion systems in this article:

-

Steam propulsion system

-

Diesel engines

-

Diesel-Electric propulsion system

-

Wind propulsion system

-

Nuclear propulsion system

-

Gas turbine propulsion system

-

Fuel cell propulsion system

-

Solar propulsion

-

Biodiesel fuel propulsion

-

Water jet propulsion

-

Gas fuel propulsion

-

Human-powered propulsion system.

Let us discuss each of these briefly. We shall be covering the working mechanism of each system and the types of vessels they are used in.

Steam propulsion systems

Steam propulsion systems use steam turbines as prime movers. The steam expands over turbines rotating them in the process. The turbines may then either power the propeller directly through reduction gears (direct propulsion) or power electric generators that power the propeller motors (turboelectric).

Titanic was powered by three main engines—two reciprocating four-cylinder, triple-expansion steam engines and one centrally placed low-pressure Parsons turbine—each driving a propeller.

With the advances in marine diesel engine technology, the use of steam turbine ships has reduced significantly in the past few decades. Further improvement in the steam turbine engine efficiency has not made it completely obsolete though. Even today, steam vessels are entering the market as LNG carriers, supertankers, ice breakers, cruise ships, FPSO vessels, and naval vessels.

Diesel engines

Diesel engines are the most commonly used type of propulsion system today. They are used as main as well as auxiliary engines and work far more efficiently than their steam turbine counterparts.

Ship’s main diesel engine

In this propulsion system, diesel engines power crankshafts that connect directly or through reduction gears to the propeller. Diesel engines are among the most versatile propulsion systems.

They can power small outboard motors as well as large engines. In fact, the largest marine engine in the world from Wärtsilä uses a diesel engine propulsion system.

Diesel-Electric propulsion system

In a diesel-electric propulsion system, a diesel engine powers electric generators that power the propeller motors.

Multiple diesel engines generate and supply electricity to the propulsion components. These components typically work on the principle of speed-controlled AC motors and drive the propeller either directly or through reduction gears.

Diesel-electric propulsion systems find use in a wide range of vessels. Their applications include mega yachts, research vessels, offshore vessels, heavy-lift jack-up vessels, passenger ferries, cable-laying vessels and cruise liners.

Wind propulsion systems

Before steam propulsion, we had sails. Sails were made of fabrics that extended over a mast to catch the wind and propel boats of varying sizes. From small recreational vessels to large galleys, wind propulsion systems were the motive force behind many of our navigational discoveries.

Recreational craft powered by wind along with diesel engines

As we shifted to more dependable propulsion systems for commercial shipping, the use of wind energy in ship design took a back seat.

However, today, the wind has become predictable besides being powerful and abundant. Presently, wind propulsion is common in sailing yachts and sailing boats.

When we talk about large vessels, wind-powered vessels are not common at all. However, many shipping companies are taking the first step in wind-powered commercial shipping. The Oceanbird is a great example of a large cargo vessel powered by wind energy.

Nuclear propulsion systems

Nuclear-powered vessels work the same way as steam turbine-driven vessels except that the heat for the steam generation comes from a nuclear reactor. The steam is then passed through the main steam turbine and/or turbogenerator for propulsion and power generation purposes.

These propulsion systems provide reduced fuel costs and superior performance. Despite the lower fuel cost, nuclear-powered vessels can be up to 50% faster than fossil-fuel ships. The carbon savings from this type of design is also unmatched. As a result, the IMO has also been pushing for more research into nuclear propulsion systems[2].

Nuclear-powered icebreaker. Photo By Anton Chmelev from St.-Petersburg, Russia – Атомный ледокол “50 лет победы”, CC BY-SA 2.0, https://commons.wikimedia.org/w/index.php?curid=2526244

Nuclear-powered vessels are commonly used in the navy for warships, submarines, and aircraft carriers. They are also used in icebreakers.

But the commercial advantages such as faster vessels and reduced fuel costs have renewed merchant ship owners’ interests in nuclear-powered crafts.

Gas turbine propulsion systems

Cut section of a gas turbine showing the compressor, combustion chamber and turbine.

Gas turbines work on the same principle as steam turbines. The chosen fluid first enters the compressor where it is compressed and sent to the next stage i.e., the combuster. In the combuster, the high-pressure air is mixed with fuel and subsequently ignited.

This adds a large amount of heat energy into the fluid which is then sent through a turbine. The turbine absorbs enough energy to power the compressor and releases the remainder gas at high pressure and high velocity into the exhaust.

The exhaust causes the gas to pass through a nozzle. This further accelerates the gas and causes it to leave the engine at an even higher velocity. The leaving exhaust applies an equal and opposite force on the system following Newton’s third law. This force is enough to give the system and the craft a forward thrust.

Gas turbines have been primarily used in the aerospace industry. Marine gas turbines, on the other hand, haven’t been as popular because of disadvantages such as high initial cost and high fuel consumption. Another disadvantage is the inability of a marine gas turbine to generate power from the cheaper but dirtier heavy fuel oil.

But changing conditions such as reduced oil prices and profitability in specific markets have caused the ship owners to reconsider the use of marine gas turbines as ship propulsion systems.

In shipping, the militaries and the navies have been the primary employers of marine gas turbines for many decades. But recently fast ferries have been employing marine gas turbines because of advantages such as a high power/weight ratio.

Cruise ships such as the MV Millenium also sport marine gas turbines as the main propulsion system. ABB has also been working on integrating heavy fuel oil into a marine gas turbine’s operation and has found some success with it.

Fuel cell propulsion systems

Fuel cells generate electricity using an electrochemical reaction. There is no combustion. The main fuel is hydrogen and the waste products consist only of oxygen, heat, and water. This makes fuel cells a very good choice from a sustainability perspective.

In a fuel cell, the hydrogen is supplied by the fuel tank to the anode in the electrochemical reaction. The atmospheric air reaches the cathode. At the anode, a catalyst separates the hydrogen molecules into protons and electrons, each of which takes a different path to the cathode. The electrons travel through an external circuit

Fuel cells in marine propulsion are scaling new frontiers. A wide range of vessels are being developed with this technology. Among these are research vessels, river vessels and push boats.

Solar propulsion

Modern technology solar boat on still lake waters

Solar propulsion has indeed become a reality in the past few years. In many vessels, marine-grade solar panels are being fitted to provide supplementary propulsive and electrical power.

This means that solar-powered vessels also have alternate means of propulsion, typically a diesel engine for days when the solar energy is not enough.

Solar-powered vessels have components such as solar panels, battery packs, MPPT charge controllers, and a computer management and monitoring system. As with other solar-powered systems, the energy accumulated from the solar panels is stored in batteries and used as needed to power the vessel.

These systems can be fit on vessel types such as oil tankers, bulk carriers, car carriers, cruise ships, recreational vessels, passenger ferries, riverboats, and coastal cargo vessels.

Biodiesel fuel propulsion

Image by macrovector_official

on FreepikBiodiesel fuels such as FAME (fatty acid methyl aster), BTL (biomass to liquid), and HVO (hydrotreated vegetable oils) can power marine engines when blended with marine diesel oil.

These fuels are fully renewable and almost 100% carbon neutral. Their handling, transport and storage are also quite simple.

These fuels are gaining ground in commercial shipping for several reasons, not the least among which is the IMO’s initiative to reduce greenhouse gas emissions (GHG). Biodiesels generally have lower sulphur content allowing them to meet IMO’s criteria. But meeting NOx limits can be a problem due to the high oxygen content in biodiesels.

When it comes to shipping applications, biodiesels are seen in tankers, container vessels, car carriers, bulk carriers, and dredgers.

Water jet propulsion

Water jet propulsion system in use in a jetski

Water jet propulsion uses a high-pressure water jet to propel forward in the water. As the jet leaves the vessel at a high velocity, it exerts an equal but opposite force on the vessel and pushes it in the forward direction. The water used in the water jet propulsion system is sourced from the surrounding seawater itself.

There are many different means to create a water jet, the simplest of which is to use a pump powered by electricity to pressurise the water. The water jet system also has other components such as a stator, suction duct, nozzle, etc. Bigger vessels may fit a propeller in the duct to create the water jet.

At the present moment, a water jet system cannot create enough power for large vessels such as oil tankers and bulk carriers. However, it can propel smaller vessels such as naval ships, tugs, trawlers and recreational vessels at very high speeds.

Gas fuel propulsion

Gas fuel propulsion systems use LNG to power ships in addition to heavy fuel oil and diesel oil. As a result, these engines are also known as tri-fuel engines.

LNG offers various benefits such as low CO2, SOx, NOx and particulate matter emissions. It is an excellent bridging fuel for the transition towards zero carbon emissions. Moreover, LNG is becoming more readily available globally.

However, issues such as methane slip still need improvement. Methane slip is when unburned packets of methane in the combustion chamber get released into the atmosphere. As methane is a much more potent greenhouse gas compared to carbon dioxide, swapping fuel oils with LNG could actually exacerbate the climate crisis instead of restricting it.

Currently, LNG-powered engines are in use on LNG carriers, container vessels, cruise ships, RORO ferries, bulk carriers, supply vessels, drillships, dredgers, and tugboats.

Human-powered propulsion systems

While we are discussing propulsion systems, let’s not forget the oldest means of propulsion for a complete picture.

Before steam engines took over, human muscle propelled all types of ships on the water. Most were assisted by windsails but in the absence of winds, humans powered these vessels through equipment such as paddles, oars, and so on.

From fishing vessels to war galleys, human-powered vessels were capable of a wide range of operations. Today as well, we can see human-powered vessels in commercial shipping as well as in recreation.

Examples of human-powered oared crafts today are racing shells, dinghies, skiffs, rowboats, sculls, gondolas and so on. We also have paddle crafts such as canoes and kayaks. Many pedal crafts are also in use.

Conclusion

We listed some of the most commonly used methods of marine propulsion in this roundup.

Apart from these, constant research is in progress to use alternatives such as LPG, biogas, methanol, synthetic diesel, ammonia, etc. As the world moves towards greener shipping, it will be interesting to see how the shipping industry evolves in the face of this challenge.

We can expect many more innovative technologies not only to be put into use but operate at the level of current technologies in the next few decades.